by AB1DQ, James M. Surprenant – 22 May 2022

One of the most formative experiences that launched me on my radio path occurred when I was about 11 years old and in junior high.

I was already in love with electronics and radio having built several simple Radio Shack kits and having spent countless hours in my grandfather’s radio workshop in our basement, devouring his stash of vintage Pop Electronics and DeVry home radio & TV repair coursebooks.

I recall that at the time, the annual school science fair was coming up and I was preparing to do my project on the world of electronics.

In those days, my dad shared an office at work with a coworker who was a ham radio operator. His name was Frank Pariseau, W1AQO, now a silent key. My dad was into the citizen band scene of the late 70s, and he would often tell me stories of how Frank would constantly try to entice him to getting his ham radio license.

One often repeated story was about the day my dad came into the office one morning to find two pieces of masking tape, a short piece followed by a long piece stuck to the wall.

Frank asked dad what that was, and dad replied, “masking tape.”

“No, no, no, Jim,’ Frank exclaimed, “that’s the letter ‘A’ – di-dah, that’s Morse Code! You now know your first character!”

“No Frank, that’s graffiti, you should take it down.”

Despite Frank’s best efforts (and mine in dad’s years), the old man would never get his ham radio license.

However, while Frank may have failed to convince my dad to get on the ham bands, he would probably have been pleased to know, that although I never had the opportunity to meeting him, I acknowledge and give thanks for Frank’s inspired act of generosity he made to me that fall that planted the seed that firmly set me on the path of a rewarding lifetime hobby in radio.

One night my dad came home from work with a surprise under his arm. He was carrying a vintage Hallicrafters S38 general coverage receiver that Frank sent him home with for me to try out.

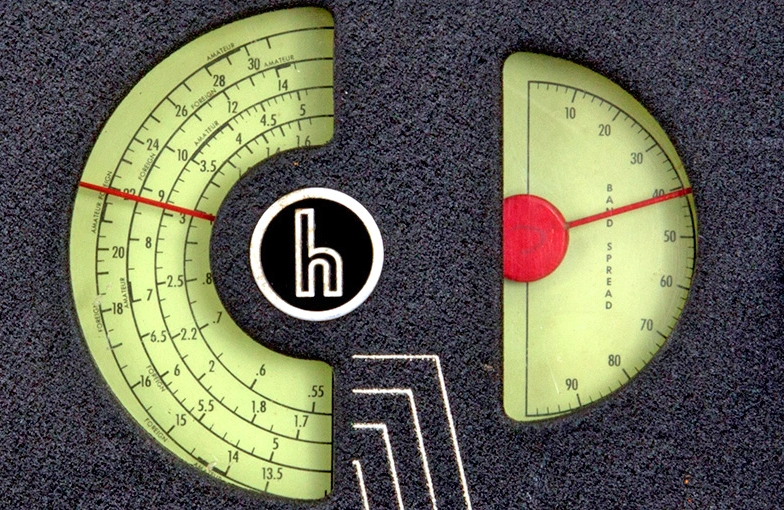

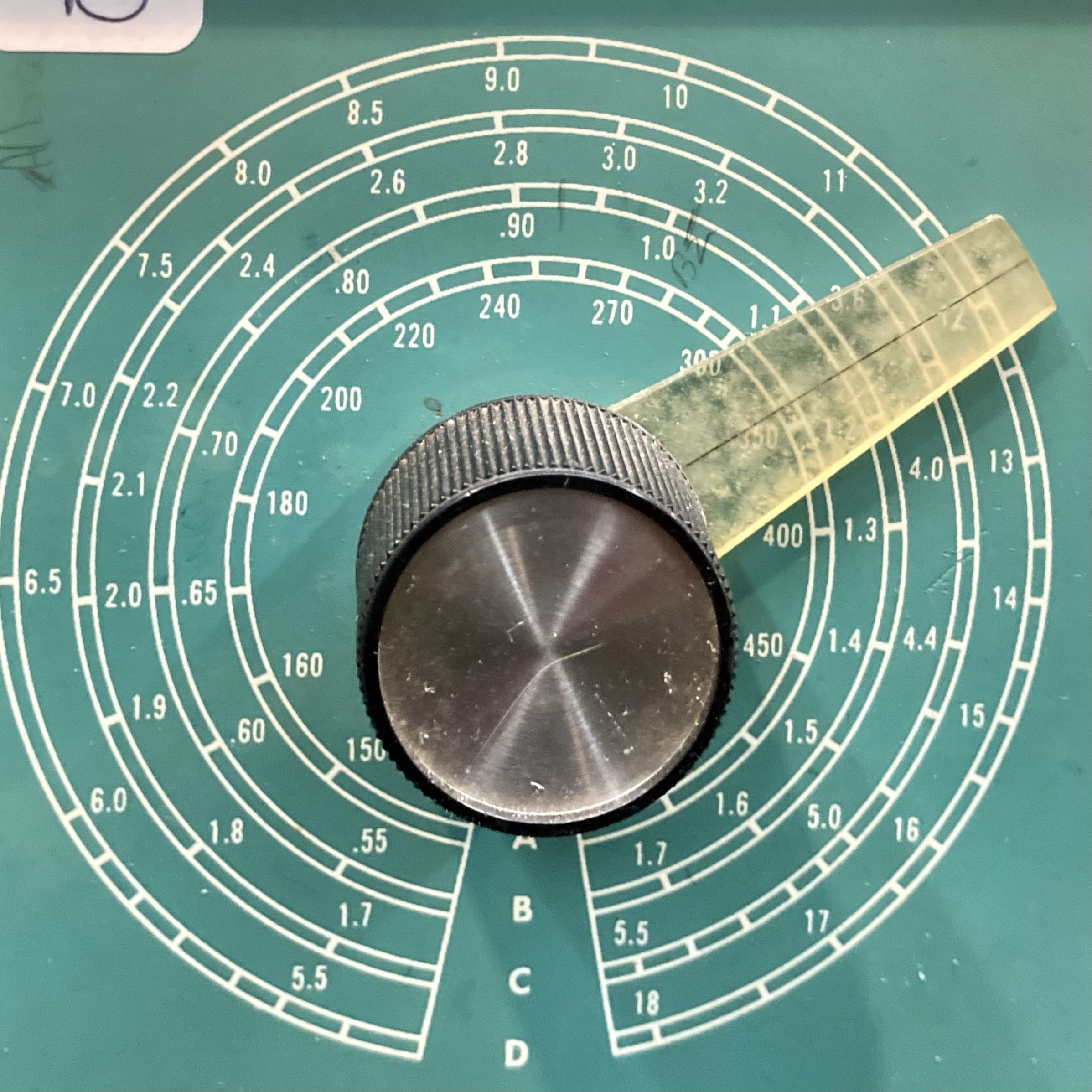

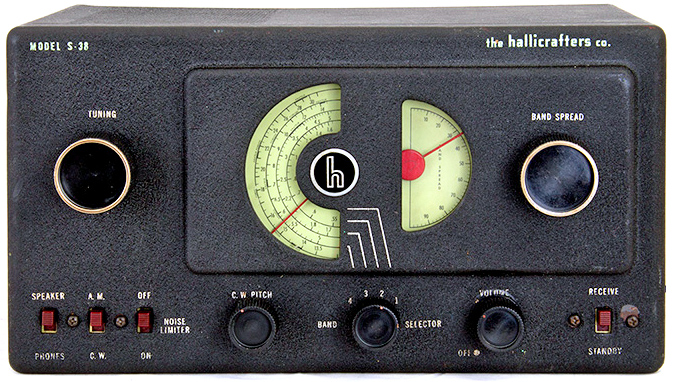

The radio was a delight for me to behold. I marveled at the beautiful dual tuning dials – the left with its four nested scales with more numbers than I’ve ever seen on a radio, and the one to the right that in sharp contrast had a single scale simply marked from 00 – 100.

Each dial had its own massive tuning knob next to it and there were other knobs and switches with labels I’ve never seen on any other radio – “AM/CW,” “CW PITCH,” “RECEIVE/STANDBY.” And the brand name, “the Hallicrafters Co.” filled my mind with curiosity.

“THE” Hallicrafters – what was a Hallicrafter? How did one become a Hallicrafter? Who were the men of this marvelous group that produced and proudly put their mark on such a magnificent radio?

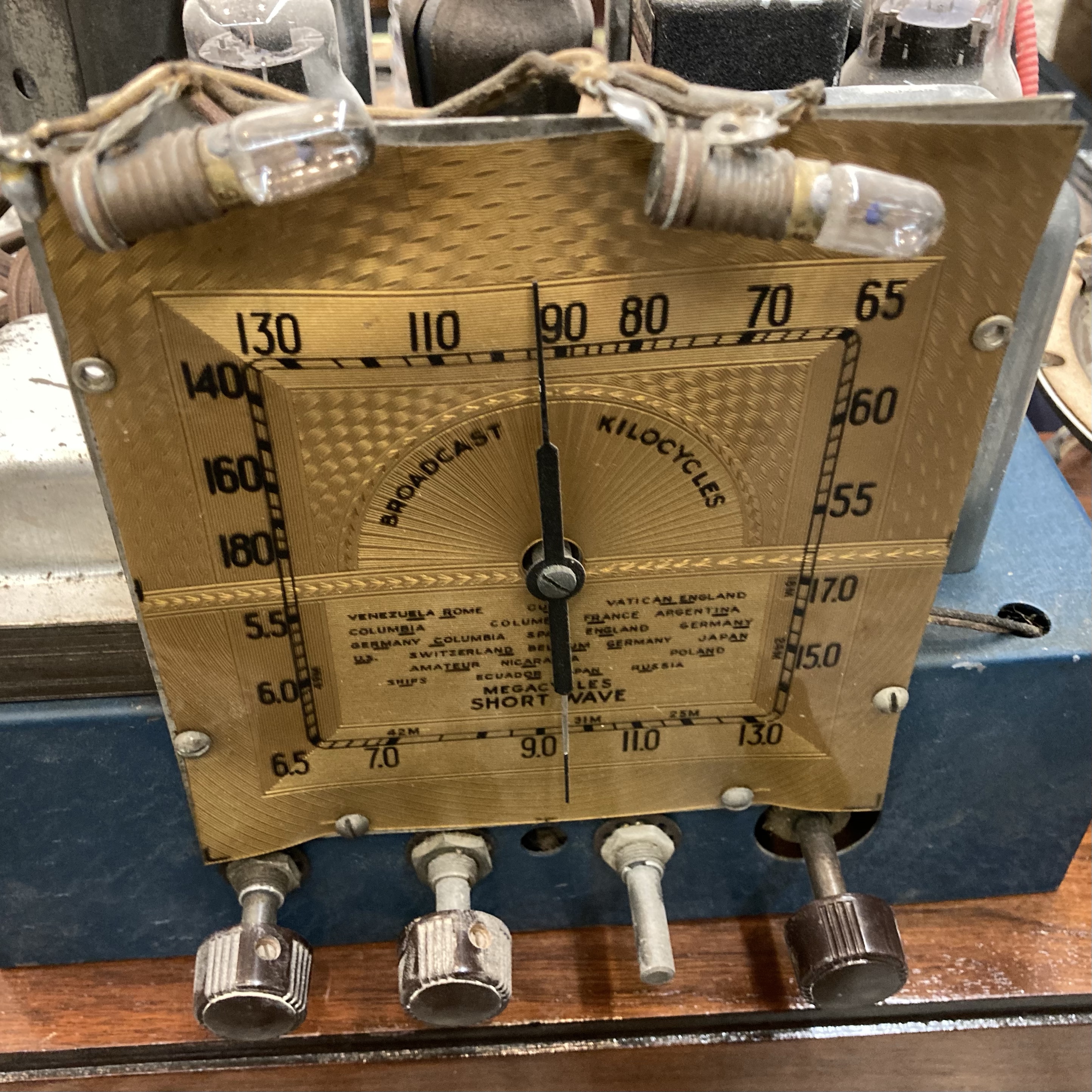

To briefly answer that last question for you, dear reader, the Hallicrafters Company manufactured, marketed, and sold radio equipment, and to a lesser extent televisions and phonographs, beginning in 1932. The company was founded by William J. Halligan and based in Chicago, Illinois, United States. From just after World War II until the company’s final days in the mid-60s, the Hallicrafters sold several lines of commercial shortwave receivers for the general public, as well as a series of ham band receivers and transmitters.

The S38 was their ubiquitous entry-level shortwave receiver intended for the general public. It was a simple transformerless All-American Five circuit that would receive the AM broadcast band from 540-1650 kHz and then continue through shortwave bands from 1.65 – 32.00 MHz over four switchable bands. The S38 was designed by French born American industrial designer Frank Loewy whose story is another fascinating rabbit hole I recommend those who are curious and appreciate 20th century design to venture down.

The S38 was surprisingly sensitive, inexpensive, simple to operate and remained in production until 1957 with regular design and minor circuit upgrades along the way. The original S38, produced until 1949, was the only radio in the series to feature a tunable BFO to allow the listener to easily peak CW and SSB signals. All following models lacked this feature and these included the S38A, launched in 1949, the S38B, launched in 1950, the S38C, launched in 1952, the S38D which came out in 1955, and finally the S38E which was introduced in 1957.

The S38, A, B and C all featured the distinctive two semi-circular tuning dials – a main dial on the left with a band spread dial to its right, giving these radios a distinctive trademark appearance. The D & E abandoned the circular dual dials for linear dial scales that occupied the majority of the front of the radio.

Reliving that first magical night

I remember my surprise when dad came home from work that night with the S38. Dad’s nightly return to our apartment each evening just after 5 pm was always a moment of excitement for my sister Kristen and me.

For many of our childhood years we’d listen to hear his car pull up and then rush to greet him as he walked through the gate of our yard. Some nights were made even more wonderful when he’d be carrying a surprise gift for us kids.

Those were the best nights when dad had a fresh roll of Kodak 620 film for my hand-me-down Brownie Hawkeye, and of course the most wonderful night came a couple years prior when he brought home “Shadow” a black Cocker/Brittany spaniel mutt who became our beloved pet for the rest of our childhood. All of dad’s wonderful surprises thrilled us, but the night dad walked in with the S38 trumps all – yes, even the dog!

Dad said we could set the radio up after dinner, which seemed to go on forever that night. Worse, after dinner I had to wait further until the table was cleared and he finished washing and drying the dishes – his evening practice of expressing gratitude for mom’s fine cooking and a means to partner with her in mealtimes.

Finally when his evening chores were done, dad brought the radio to my bedroom with a spool of hookup wire, his wire nippers and a flat blade screwdriver. He set the radio up on my desk, using the tools to cut a 20′ wire antenna that he attached to the A1 terminal on the back of he radio. I crawled under the desk to plug in the power cord and we were ready to go.

Dad pointed out the on/off/volume control and invited me to turn the radio on. I did and watched eagerly as the dial lamps came on brightly and then dimmed as the tubes began warming up. A few moments later and for the first time in my life, I heard was the beautiful strange syncopated sounds of Morse code coming from the built in speaker.

I of course had no ability to understand what I was hearing, but I was mesmerized by the sound of the rapidly sent dits and dahs. I pondered what urgent messages were being sent and I envisioned radio operators in their darkened shacks hunched over their Morse code keys before stacks of glowing radio equipment. A child’s imagination is a wonderful thing!

After listening for a while, I tried turning the right hand bandspread dial slowly up and down, and continued picking up many other stations sending Morse Code. I was struck how these signals varied in terms of tone, strength and speed. I discovered that by turning the CW PITCH knob I could change the tone of the dits and dahs and peak their strength. Most of the code I was hearing was being sent rapidly, probably 20-25 words per minute or faster, but then there would be other stations sending slower code at 12 words per minute or less. It was all music to my ears.

Next I tried turned the main tuning dial up and down across the bands, without knowing the band plans or where I might find specific types of stations. Still by using my crude hunt and seek tuning method, the sounds of Morse Code were soon replaced by the distinctive distorted Donald Duck sound of hams operating phone on sideband.

I was captivated listening to the back and forth conversation between a pair of hams, exchanging a series of numbers (signal reports, power output, antenna specs), and some then ‘chewing the rag,’ \shooting the breeze and talking about whatever was on their mind – simple friendly conversation. I would marvel hearing the ham operators state where they were operating from – distant cities and towns across the US, being heard so clearly, and I was further thrilled hearing each operator routinely conclude his turn by giving his callsign. Wow – simply – wow!

Over the next few nights I continued to explore the shortwave bands and discovered more of what they had to offer. Hearing Morse code was magical, even though I couldn’t comprehend what was being communicated, and as wonderful as the hams on sideband were, most of their conversations began to sound the same.

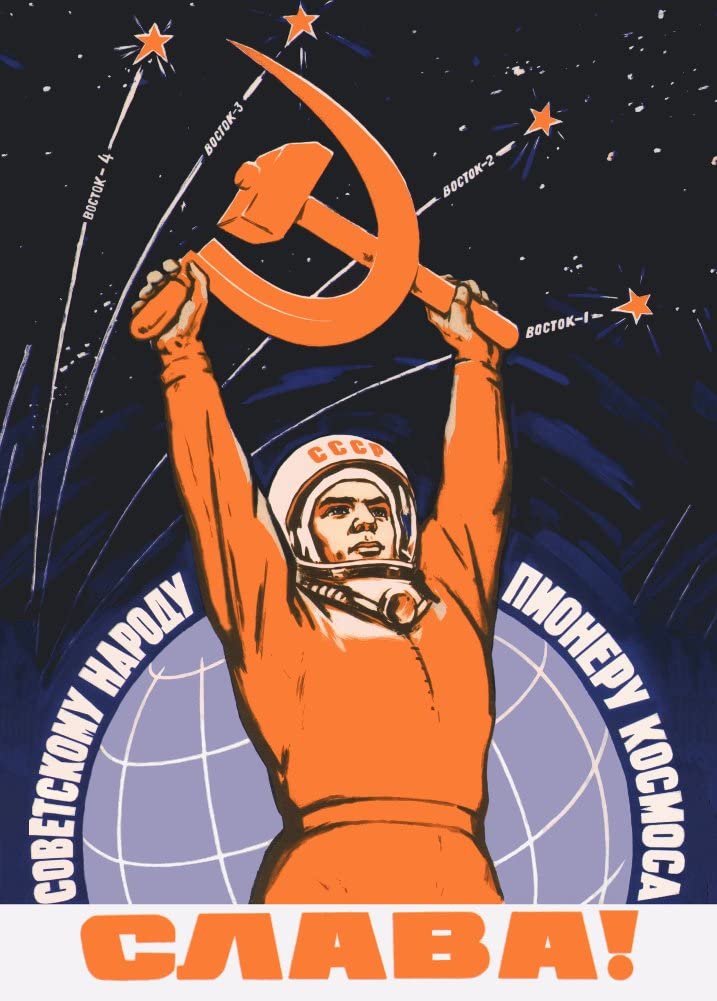

This is when I first heard international shortwave broadcast stations such as the BBC, the Voice of America, Radio Moscow, and dozens and dozens of others from all over the world. Of course growing up in the 70s, I was coming of age in the height of the Cold War and all nations, whether from the East or the West, would have state sponsored shortwave station that broadcast the daily news and their editorial views nightly. It was a real education to hear how the same global news story could be reported so differently when presented by a Western station such as VOA, BBC or Deutsche Welle, or by an Eastern bloc station like Radio Havana, Radio Tirana or Radio Kiev.

The international shortwave bands were chock full of Cold War propaganda!

After the news & views content that started every broadcast, the majority of these international broadcast stations would then move onto cultural and entertainment programming. Several had ‘mailbag’ programs where listener letters were read on the air and responded to. Some stations had language lesson programs, some reported on local cultural customs and seasonal events such as festivals, and most had ethnic music programs.

What a world that Frank’s simple gift of the S38 opened me up to. Recall that these were the days long before the internet, streaming video, and even basic cable. Up to then I was living in a world of three network TV stations plus the PBS station, and all that AM and FM radio had to offer.

More about the S38

As I mentioned, the S38 was ubiquitous in its day, and despite having concluted production 60 years ago, these radios remain ubiquitous in the radio hobbyist community today. It’s almost impossible to attend a ham radio flea market without seeing several, and there are dozens continually up for bids on eBay.

Similarly, there are many excellent web resources where S38 enthusiasts have published the receiver’s history, technical data such as schematics and servicing instructions covering essentials such as recapping and realignment, as well as performance and safety mods. I will conclude this blog entry below with a few links to some of my personal favorite S38 websites. But, while web certainly didn’t need another S38 fan page, given the radio’s foundational role in my radio story, I would be lacking had I never included a post such as this in my radio blog.

S38 Specifications

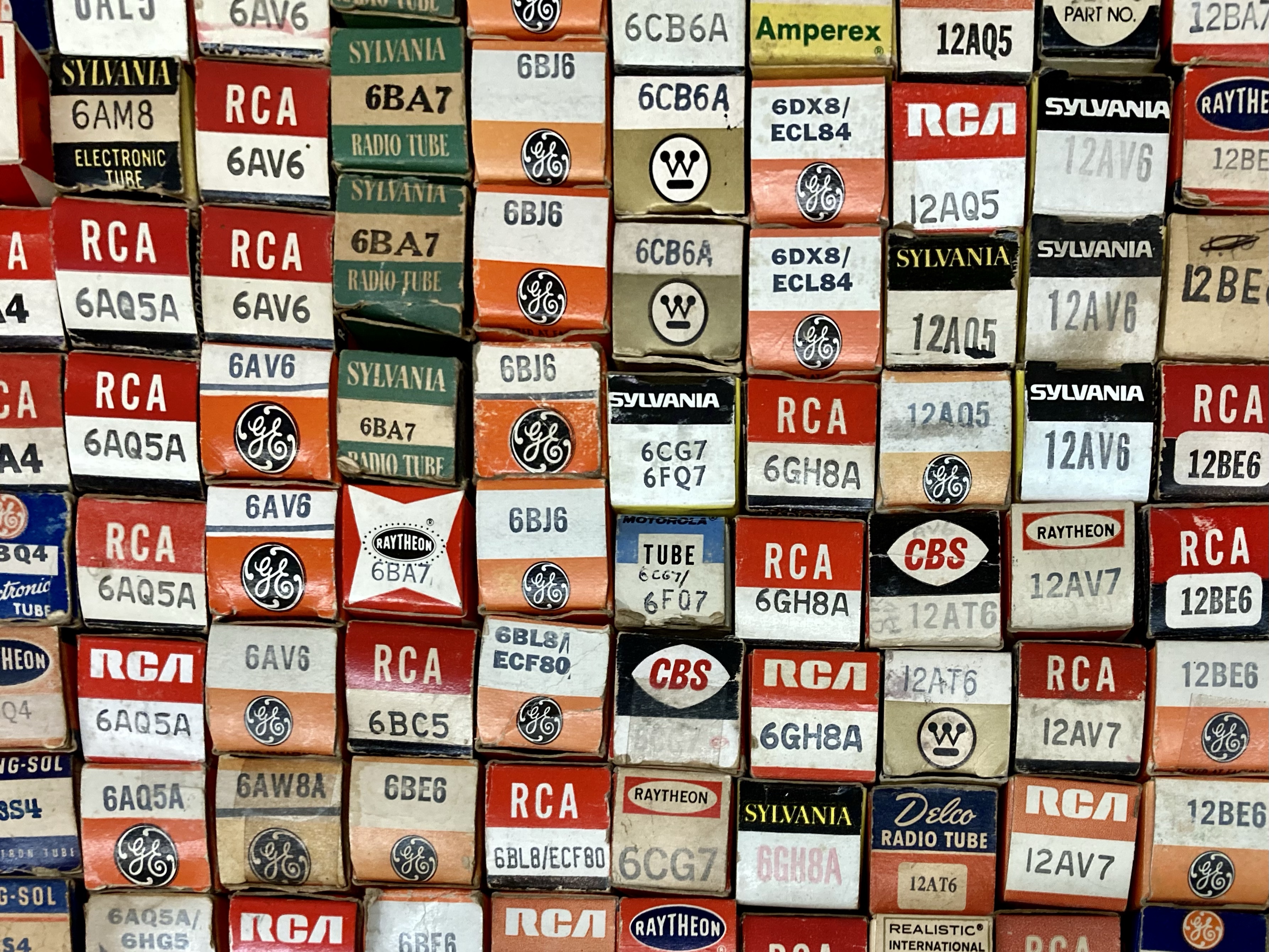

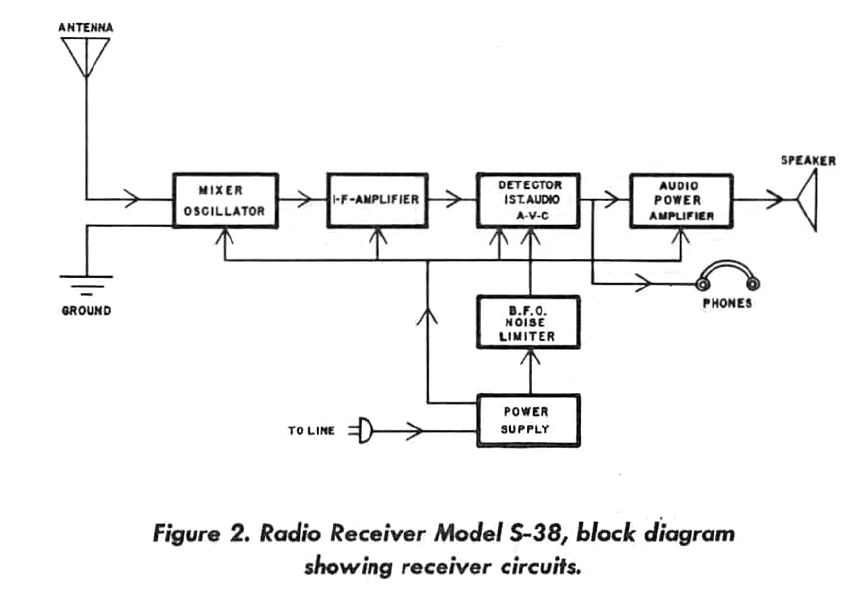

The S38 is a superheterodyne receiver using frequency mixing to convert a received signal to a fixed intermediate frequency (IF) which can be more conveniently processed than the original carrier frequency. Quoting the S38 1949 user manual…

Radio signals are picked up at the antenna and fed to the antenna coil of the mixer stage where the desired station signal is selected by a resonant circuit and fed to the mixer tube. At the same time, the oscillator section of the tube generates a local r-f signal which is mixed with the incoming station signal. An intermediate frequency of 455 kc is selected by the first i-f transformer and fed to the i-f amplifier tube where it is fed throught the second i-f transformer to the dectector-first audio amplifier where it is demodulated. The audio component of the signal is then amplified by the triode section of the tube and capacity coupled to the audio output tube where it is further amplified and fed to the speaker.

The Hallicrafters Co., Installation and operating instructions for the model S-38 radio receiver, August, 1946, 94-162-A

The S38 circuit was the popular “All American Five” design, which was used in hundreds of radio sets by practically every radio manufacturer of the era. The AA5 was a sensitive superheterodyne circuit that lacked a power transformer and could be operated using either an AC or a DC power supply of 115-125 volts. By not including a power transformer, AA5 radios provided an inexpensive radio choice for the consumer of the day.

However this cost saving feature also contributed to making these radios a bit more dangerous for the user. Typical of radios and electric appliances of the 1940s, the S38 did not have a polarized plug on its line cord which means you have a 50% chance of connecting the chassis ground side of the radio to the household ‘hot’ connection rather than the safer neutral connection. This had the potential of resulting in a dangerous electric shock for the user if the rubber washers that insulate the chassis from the cabinet deteriorated and failed. Because of how the on-off switch was wired in this ‘hot chassis’ design, the risk existed even if the radio was switched off.

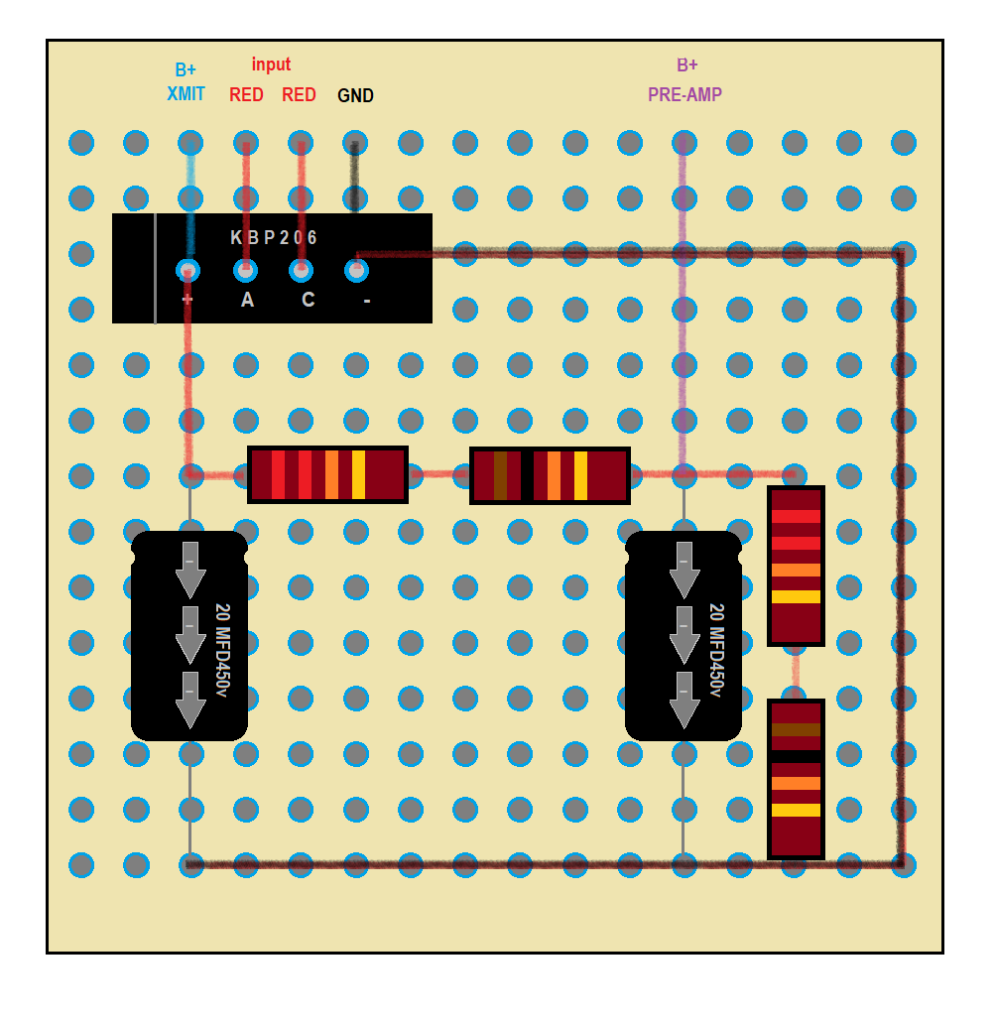

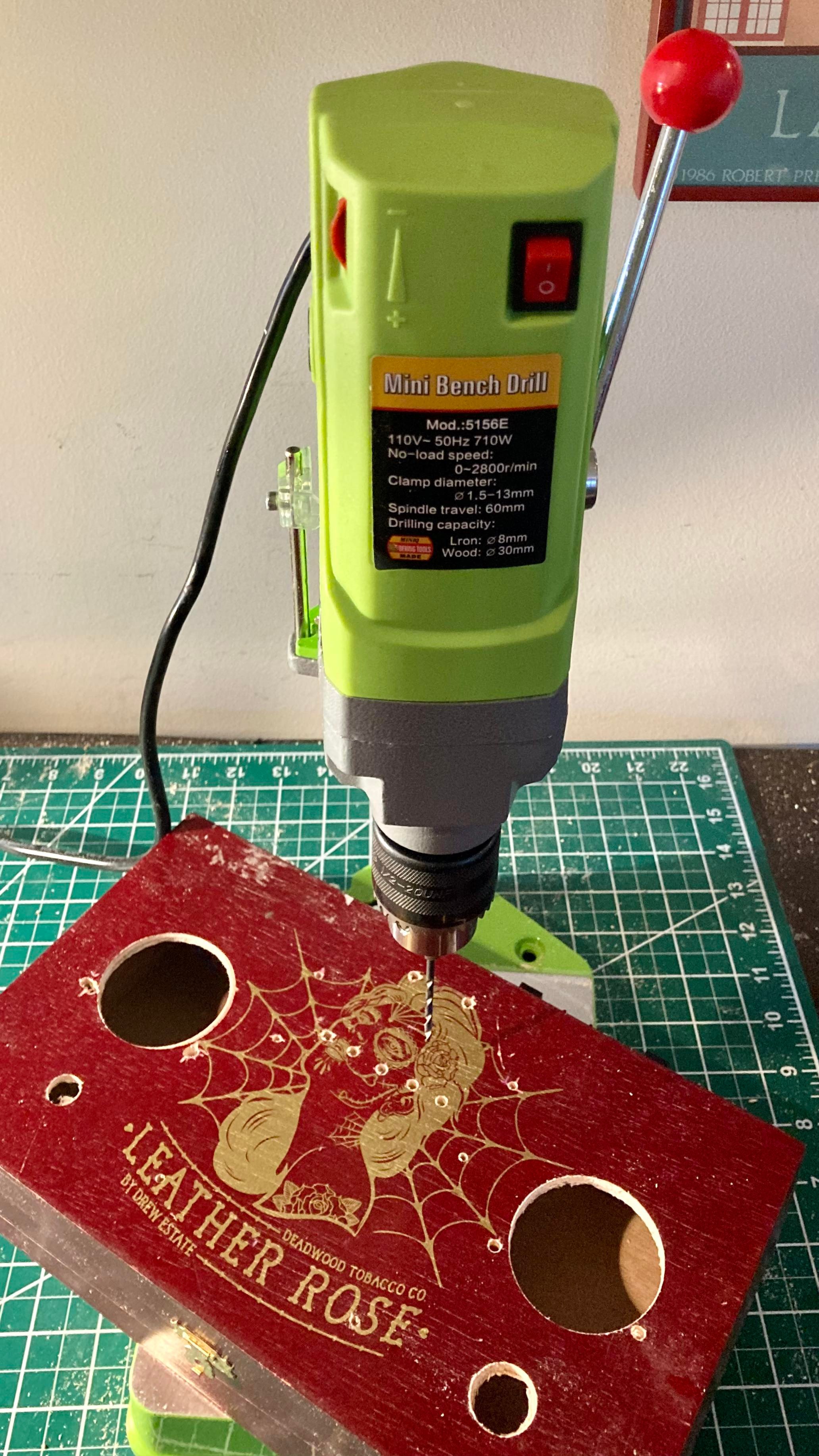

An essential practice for anyone servicing or restoring an S38 today is to install a polarized plug and wire it so the neutral wire goes to ground and the hot lead is connected to the power switch which is relocated to pin 2 of the 35Z5 tube on the opposite end of the filament chain. Adding a fuse to both power leads is also a good idea. Whenever I restore an S38, in addition to replacing the leaky wax and electrolytic capacitors, I make the following modification.

S38 Links

- Phil Nelson has maintained his excellent website dedicated to restoring the Halicrafters S38 since 1995 and its an excellent starting place if you want to learn more about the S38. He also has instructions on how to add an S-meter to your radio.

- WD4EUI, Allen Wooten of Huntsville, Alabama has an excellent page on his restoration of an S38C complete with excellent detailed photos including several on repairing damaged IF transformers.

- The Sam’s Photofact for the original S38 model, including schematics, parts list and alignment instructions can be obtained as a PDF here.

- John Fuhring describes his restoration of his S38B complete with detailed photos and a schematic for a mod to add an FET based BFO here.

- Read reviews of the S38 from ham radio operators on the eHam product review site here.

- AI4FR, John Whitt of Dade City, Florida has a detailed page dedicated to his resto-mod of an S38 including his safety modification to prevent shocks.

- VE7SL, Steve McDonald of British Columbia describes his S38 restoration here.

- YouTube video: Hallicrafters S-38, The AA5 On Steroids, Arthur’s Hallicrafters Kitchen and Audio Lab

In Conclusion…

As I said, there are no shortages of websites dedicated to S38 restoration and use. Thanks for visiting mine and reading my personal story.

Do you or did you own an S38? Which model was it? Did you restore it or modify the radio? Do you still use it today? What are your thoughts or impressions? Drop me a line a james@ab1dq.com and share your story!